Request A Free Consultation

Request A Free Consultation

LABO 20 30 XPL P Batch Freezer

Electronic Batch Freezers for Artisanal Gelato

Quality

Six variable freezing programs, suited to different types of production: Gelato, Sorbetto, Slush Fruit, Gelato Crystal, Fruit Crystal, Ice Cream.

Performance

Hard-O-Tronic®: This is the exclusive system for an excellent gelato.The LCD screen constantly displays the values of the programmed consistency and that of the gelato in the batch freezer. By pressing on the arrows you can always change it, to obtain your own ideal gelato.

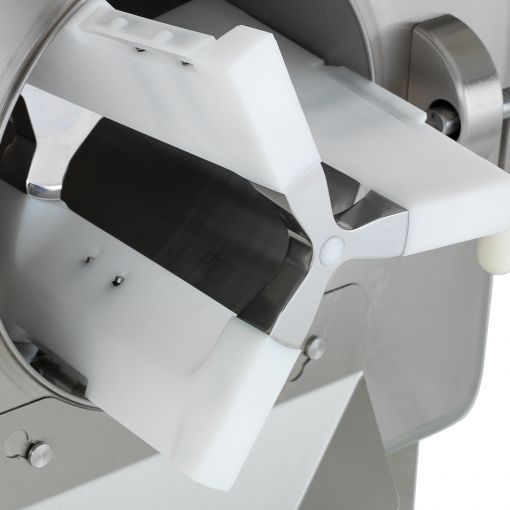

POM Beater: The beater has no central shaft. Its POM blades - impenetrable by the cold - facilitate the complete extraction of the gelato every time. Sturdy yet light, it has self-adjusting scraper blades to maintain the cylinder clean and efficient.

Post Cooling: To maintain the consistency of the gelato during extraction, the post cooling function injects cold into the gelato as it comes out of the cylinder.

Convenience

All commands remain accessible when the hopper cover is open so that the operator can start production while adding mix.

The operations of adding mix and extracting gelato are done standing straight.

Shelf mat. Designed to keep trays and tubs firmly in place during gelato extraction.

Optional Dispensing Door. The Ideal accessory for filling take away containers and various cake or monoportions molds with the Crystal program.

Optional: Steel door. To replace the standard polymer door.

Scan the QR Code on the front of the machine to access the most up to date equipment information: Instruction Manual, Carpi Care kit & Carpi Clean kit.

Safety

Reduced risk of injury, with corners even more rounded where the operator works.

Optional: Teorema

With Teorema, production continuity is guaranteed thanks to facilitated assistance through monitoring and diagnosis over the internet, using PCs, tablets, and smartphones.

Hygiene

The extraction chute is removable to facilitate the removal of all gelato residue, for complete cleaning.

Hand-held stainless steel shower with ergonomic on and off switch.

The new stainless steel sprayer is located on the front of the machine for an easier cleaning of the cylinder and the chute, and to avoid cross maneuvers with the door. The sprayer can also be locked to facilitate handling during use.

Scotch-Brite treatment of the sheet metal for quick cleaning.

The cylinder and front panel are a single piece for maximum cleanliness and hygiene.

Carpi Care kit - Carpi Clean kit: request them from your dealer to always keep your machine hygienically perfect.

| Hourly production | |

|---|---|

| kg | 18/30 |

| lt | 25/40 |

| Mix per freeze | |

| Qty. max. kg | 5 |

| Qty. min. kg | 3 |

| Quantity per cycle | Programs | |

| Cremolata | kg | 5 |

| Cremolata | min. kg | 3 |

| Crystal | max. kg | 5 |

| Crystal | min. kg | 3 |

| Electrical | |

| Condenser | Water* |

| Hz | 50 |

| Ph | 3 |

| Volt | 400 |

| Fuse Size A | 12 |

| Rated Power Input kW | 4 |

| Dimensions | |

| Dimension at base Depth cm | 65 |

| Dimension at base Height cm | 140 |

| Dimension at base Width cm | 52 |

| Net Weight kg | 230 |

| Note | |

| Note | Performance values refer to 25°C room temperature and 20°C water temperature in the condenser. The quantity per cycle and production time vary based on mixes used. The “Max” values refer to classic Italian artisanal gelato. *Air condenser available with surcharge. The above dimensions and weight refer to the water cooled version. Labo XPL machines are manufactured by Carpigiani using a UNI EN ISO 9001 Certified Quality System. All specifications mentioned must be considered approximate; Carpigiani reserves the right to modify, without notice, all parts deemed necessary. |

Related Products

Artisan Gelato Case Study

.jpg)

.jpg)